Groningen Seaports

Groningen Seaports is the port authority for Delfzijl, Eemshaven and the adjoining industrial sites. They provide a complete package of port services to its clients from logistics and infrastructure services to the maintenance of sites.

The company has a long history managing the seaport of Delfzijl, which until 1819 was managed by the Dutch Government. Since 1819, it has been managed by the province and local governments and has been called Groningen Seaports since the year 2000.

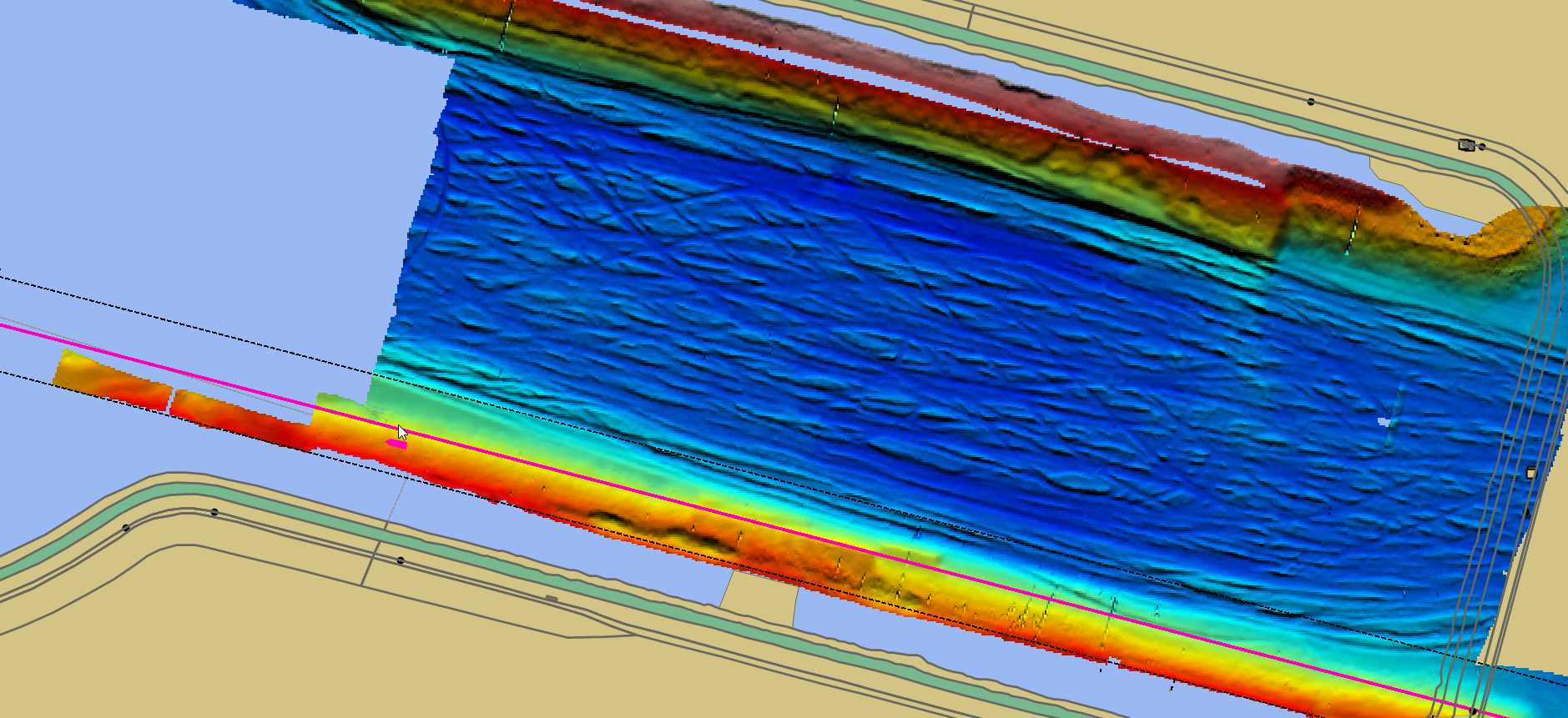

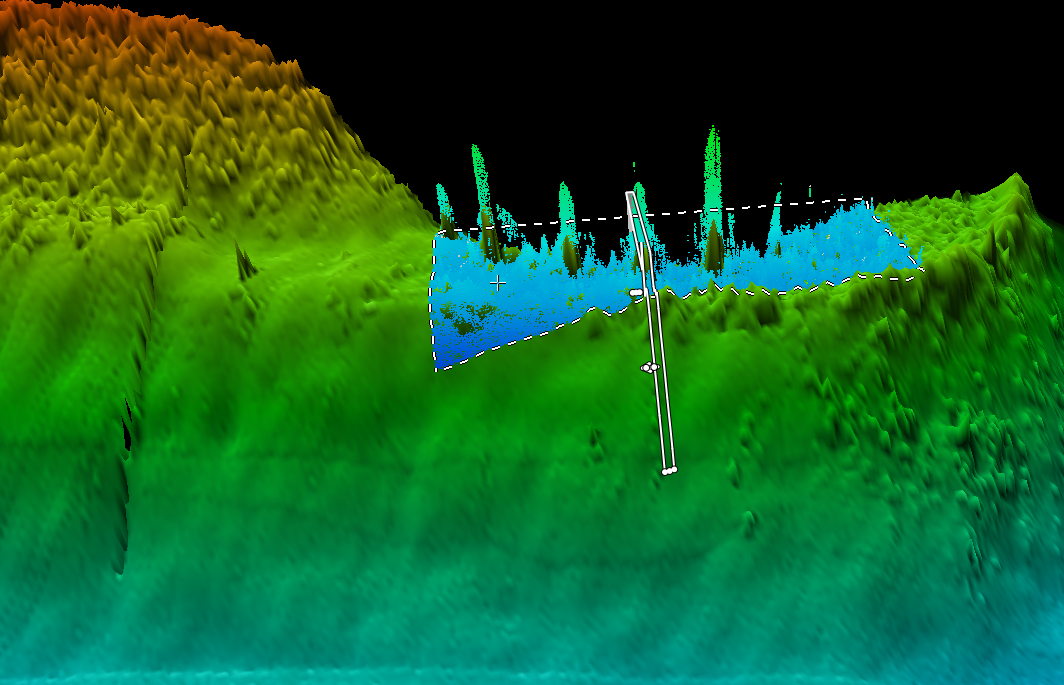

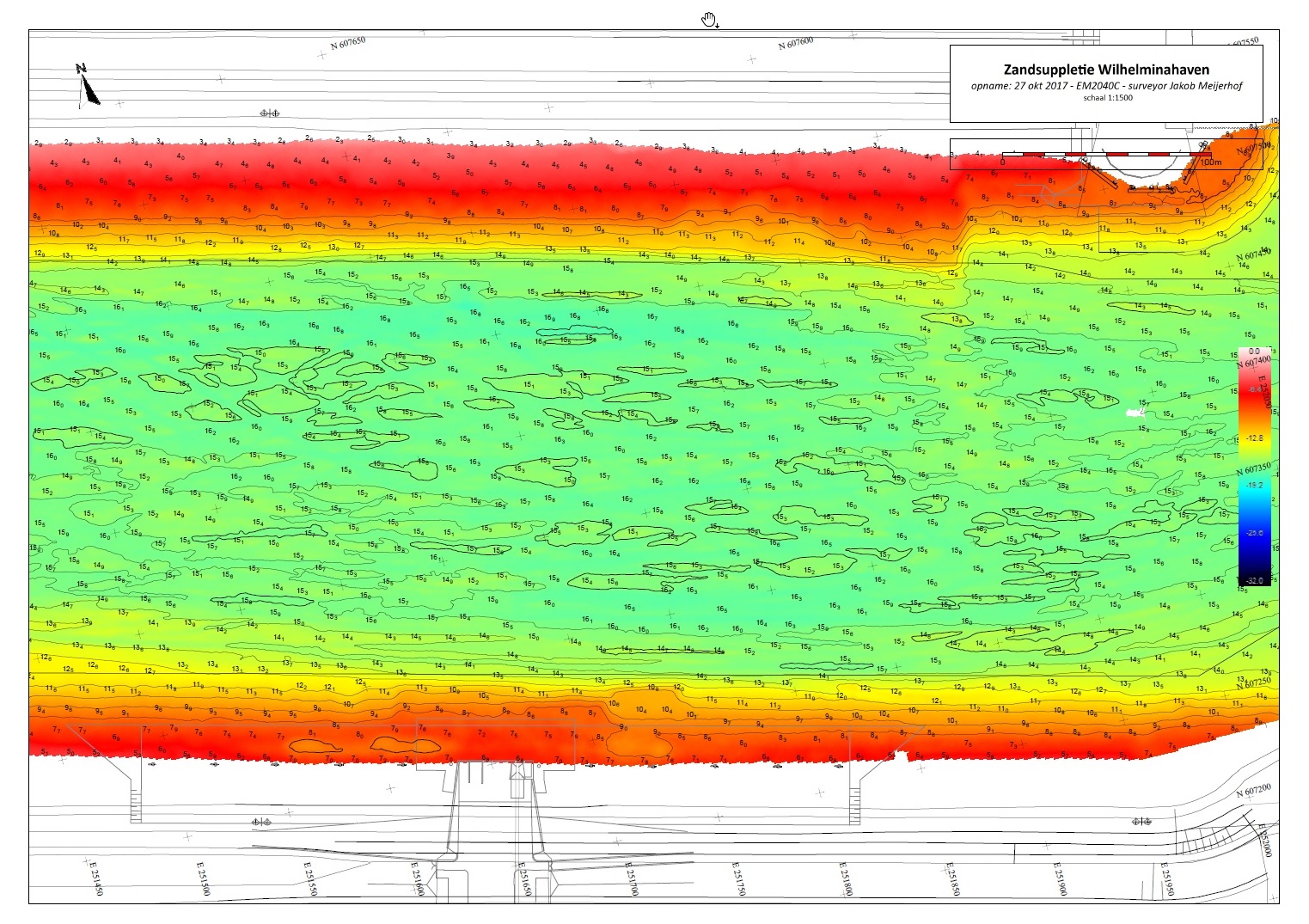

Groningen Seaports currently has 80 employees. The Dredging & Surveying department is responsible for the safety of navigation and for the ports accessibility for cargo vessels, regular hydrographic surveys play a key role in the port’s availability. With the regular surveys that Groningen Seaports are doing, they have an exact knowledge how the ports’ bathymetry looks and where special attention is required in order to prevent siltation of the port. Their vessel “Havenschap 1” has a Kongsberg EM2040 multibeam system installed in a moonpool together with a Kongsberg EA400 singlebeam dual frequency echosounder. With the 210kHz and 33kHz channels of the singlebeam, Groningen Seaports gains even more knowledge about the fluid mud layer floating above the seabed in the port which is causing siltation of the port. Monitoring this fluid mud layer is a crucial part of the work that the Havenschap 1 and its crew is doing. Until 2012 their multi-tasking surveyor navigated the boat and collected hydrographic data simultaneously without loosing an eye on perfect data quality. For health and safety reasons it was decided in 2012 there should be two men on board.

With only one person doing the survey and steering the boat an efficient way of data collection, cleaning and charting was required. QPS products enabled this efficient workflow and continues to do so. Groningen Seaports has been a QPS client since 2000, when QINSy 7.5 was brought to the market.

DATA QUALITY

Groningen Seaports find QINSy offers great tools for their surveyor and skipper to QC data during collection.

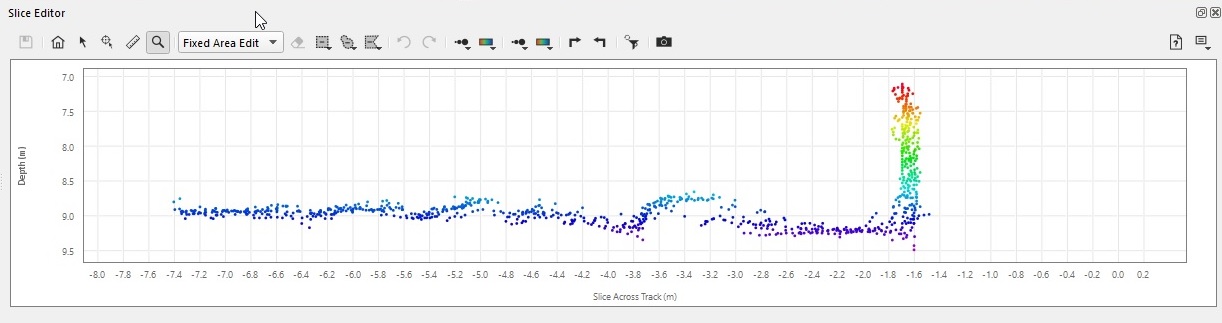

When we notice something is not right with the data, we can quickly erase the erratic data and then re-do the line. This way we don't lose time on processing and de-spiking the data. The QINSy online displays and QC tools are very powerful.

SUCCESSFUL TRANSITION FROM QLOUD TO QIMERA

” Also the workflow with Qimera for filtering and de-spiking the data works really good for us. Qimera is fast de-spiking the data. Recently we’ve moved from Qloud to Qimera. Since we are using Qimera, we’ve reduced the time de-spiking the data with 50%! We are happy QPS users”. This efficient workflow enables them to deliver the data to the dredging company within one hour, following a four hour survey. They take the data from Qimera into Processing Manager and then using Processing Manager for calculating volumes and for creating the final depth charts.

TECHNICAL SUPPORT

If there are questions about software or technical problems, Groningen Seaports get in contact with QPS Support.

QPS offers excellent support; when we contact the Support department, we are always immediately being helped. This is also why we are choosing QPS

For more about Groningen Seaports, please visit https://www.groningen-seaports.com/?lang=en

September 2018